Harnessing the Power of Artificial Intelligence and Machine Learning in CNC and VMC Probing Systems

- triotechcncsolutio

- Jul 28

- 4 min read

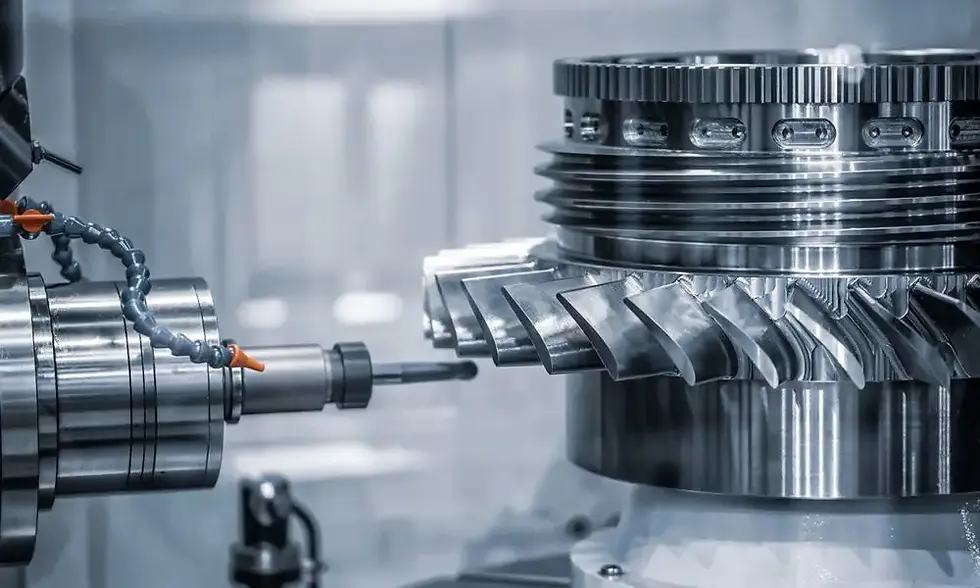

In today's fast-paced manufacturing landscape, the integration of artificial intelligence (AI) and machine learning (ML) is not just a trend; it’s reshaping industries. Among the key areas affected are CNC (Computer Numerical Control) and VMC (Vertical Machining Center) probing systems, which are vital for improving accuracy and reducing downtime. This blog post dives into how these technologies are harnessed to elevate machining processes, ultimately enhancing operational efficiency and product quality.

Understanding CNC and VMC Probing Systems

CNC and VMC probing systems are essential in modern manufacturing environments. They automatically measure part dimensions and verify the placement of features while manufacturing. Probing uses sensors to collect data on the shape, size, and surface characteristics of a workpiece. This process provides invaluable feedback, allowing CNC machines to operate with precision.

For example, a study showed that effective probing can reduce manufacturing errors by up to 20%, ensuring that parts fit within strict tolerances. By incorporating AI and ML, these systems can better analyze data and adapt to changing conditions, leading to increased efficiency.

The Role of Artificial Intelligence in Probing Systems

AI significantly improves the capabilities of probing systems. One of the most compelling advantages is the ability to process vast amounts of data quickly. Traditional probing systems often depend on fixed algorithms to analyze measurements, which limits flexibility. AI-enhanced systems continuously learn from data input, improving performance in real-time.

For instance, when an AI system identifies a pattern in measurement data, it can automatically adjust the probing strategy. This kind of adjustment can lead to a 25% reduction in errors and minimize rework on parts that fail to meet specifications. As the AI learns, it becomes more autonomous, streamlining machining processes.

Harnessing Machine Learning for Enhanced Performance

Machine learning, a key element of AI, trains systems to learn from experience without needing detailed coding. In CNC and VMC probing, ML contributes to performance enhancement through predictive analysis and process optimization.

Probing systems equipped with machine learning can analyze historical data to foresee potential production issues. For example, significant trends in vibration or temperature can indicate when components are likely to fail. This predictive maintenance style not only boosts machine uptime but can extend equipment lifespan by 15% through timely interventions.

Machine learning also supports adaptive probing strategies. Unlike traditional methods that use static paths, ML allows systems to adjust on-the-fly based on changing factors like material properties or tool wear. Consequently, manufacturers witness sharper measurements and improved product quality.

Improving Workflow with AI and ML

Incorporating AI and ML into CNC and VMC probing systems enhances workflow efficiency alongside precision. These intelligent systems automate data collection and analysis, simplifying operations.

For example, an AI-based probing system can adjust its probing sequence in response to real-time measurement feedback. This automation reduces the need for human input, allowing operators to concentrate on higher-value tasks. As a result, some manufacturers have reported a 40% increase in productivity by utilizing AI-enhanced tools.

Moreover, real-time feedback from AI and ML systems enables operators to spot process inefficiencies quickly. By identifying bottlenecks, manufacturers can rectify issues rapidly, improving throughput and slashing production cycles.

Case Studies: Success Stories in AI-Driven Probing

The impact of AI and machine learning on CNC and VMC probing systems has been notable across various sectors.

One automotive manufacturer implemented AI-driven probing systems in their assembly line. This innovation led to a 30% reduction in rework due to part misalignment. The AI system learned from each output, refining probing strategies that resulted in tighter tolerances over time.

Another case involved a precision engineering firm battling dimensional variations in their products. By employing machine learning algorithms, they developed adaptive probing methods that adjusted dynamically based on data trends. This change resulted in a significant increase in product quality and a marked improvement in customer satisfaction due to greater consistency.

Future Trends in AI and ML for Probing Technologies

Looking ahead, AI and machine learning are set to play a critical role in evolving CNC and VMC probing systems. Several trends are emerging that could transform the industry:

Integration with IoT: Merging AI-powered probing with Internet of Things (IoT) technologies will offer real-time insights and remote monitoring capabilities. This synergy allows manufacturers to gain enhanced visibility into operations, informing their decisions effectively.

Advanced Data Analytics: Applying big data analytics to probing data will deepen insights and improve decision-making. Predictive analytics will evolve, enabling manufacturers to anticipate production challenges more accurately.

Enhanced User Interfaces: New user interfaces incorporating AI will simplify data interpretation, allowing operators to conduct complex analyses without extensive technical training.

Automation and Robotics: Combining AI with robotics will further boost automation in manufacturing. Probing systems could become fully autonomous, reducing human error and increasing overall efficiency.

The Path Forward

The integration of artificial intelligence and machine learning into CNC and VMC probing systems signifies a monumental leap in manufacturing technology. By enhancing data processing, optimizing workflows, and enabling adaptive probing strategies, these systems are setting new standards for precision and productivity.

As the industry evolves, the potential for AI and ML in probing applications will only grow. Manufacturers looking to maintain a competitive edge should consider investing in these technologies. This investment can result in substantial cost savings, improved product quality, and heightened customer satisfaction over time.

Comments