Unlocking the Secrets of CNC and VMC Technology in Modern Manufacturing

- triotechcncsolutio

- Jul 7

- 4 min read

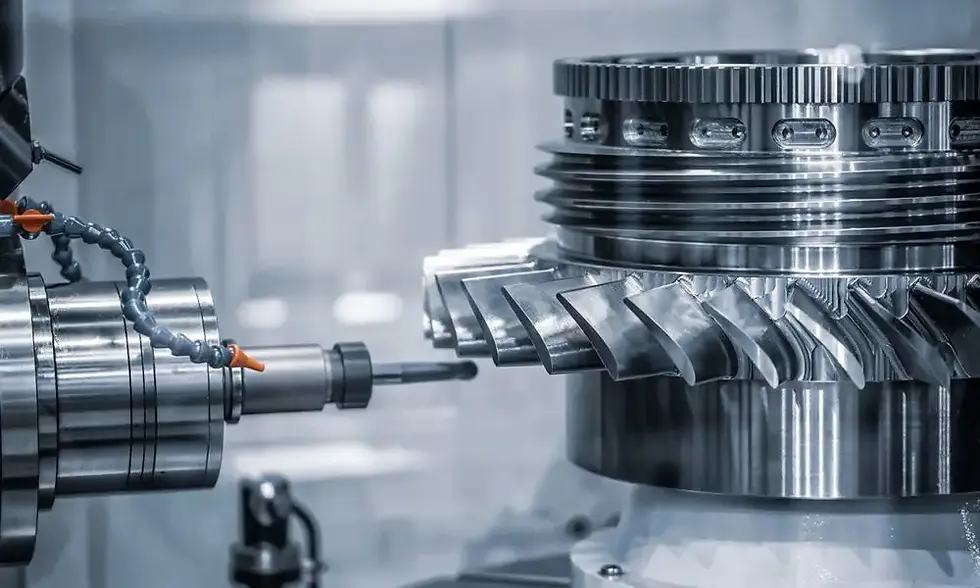

In today's fast-paced world of manufacturing, precision and efficiency are more important than ever. With competition ramping up and customer demands increasing, businesses must find ways to enhance their production processes. Enter CNC (Computer Numerical Control) and VMC (Vertical Machining Center) technologies. These innovations have dramatically transformed the way products are designed, manufactured, and delivered. It is essential for anyone involved in manufacturing to understand these technologies and their impact.

What is CNC Technology?

CNC technology automates the control of machine tools using specialized software. In the past, skilled operators manually controlled machinery, which often led to slower production rates and a higher likelihood of errors. For instance, a manual milling process could take hours for intricate designs, while CNC machines can execute the same tasks in a fraction of the time.

By using computer software to dictate the movements of machines, CNC technology allows manufacturers to create complex shapes with high precision. This shift not only enhances production speed but also maintains consistent quality, leading to lower rejection rates. For instance, aerospace companies have reported a 30% reduction in error rates since adopting CNC technology. Industries such as automotive and electronics also benefit greatly, with CNC machinery making it possible to produce components that are more reliable and consistent.

The benefits of CNC extend beyond just speed. For example, the ability to quickly switch between different production runs makes CNC machines ideal for manufacturers dealing with a variety of products. This capability can reduce setup times by up to 50%, allowing for a more flexible manufacturing operation.

Understanding VMC Technology

VMC, or Vertical Machining Center, is a subtype of CNC machine that features a vertical spindle orientation. This unique design offers several advantages for material removal, allowing tools to move along several axes—typically three to five—effortlessly. VMCs excel in operations such as drilling, milling, and tapping, making them a core component in many manufacturing processes.

For instance, a VMC is often used to create parts for high precision applications, such as turbine blades in the aerospace industry. These parts require meticulous machining that can be performed efficiently on a VMC setup. In fact, VMC machines can achieve tolerances as tight as 0.001 inches, which is crucial for such delicate components.

Applications of CNC and VMC in Manufacturing

CNC and VMC technologies have opened a world of applications in various manufacturing sectors. Here are some key examples:

Aerospace Industry

In aerospace, manufacturers rely on CNC and VMC technologies to produce components such as turbine blades and aircraft frames with remarkable precision. These parts can go through complex machining processes that demand a high level of accuracy. Statistics show that companies implementing these technologies report a 40% increase in production speed for critical components.

Medical Equipment Production

The medical sector has stringent safety standards, requiring that equipment and devices meet high precision benchmarks. CNC and VMC technologies enable manufacturers to produce intricate components, such as surgical instruments and implants, that must adhere to these exacting standards. For example, CNC tools facilitate the creation of custom prosthetics, helping to improve patient outcomes.

Automotive Manufacturing

In automotive production, the efficiency of CNC and VMC machines is evident in the rapid production of essential components. They can be utilized for machining engine blocks or manufacturing transmission cases. Consequently, automotive companies reported up to a 25% faster assembly line process after integrating these technologies.

Electronics

The electronics manufacturing field has seen great advancements thanks to CNC techniques. The production of complex circuit boards and micro-components is tailored to meet the tight tolerances required for reliability. The ability of CNC machines to automate production makes it possible to create designs that were previously too intricate to manufacture efficiently.

Benefits of Using CNC and VMC Technology

The adoption of CNC and VMC technologies brings significant advantages to the manufacturing landscape. Here’s a closer look at why these machines are becoming increasingly popular across various sectors:

Enhanced Accuracy

One of the standout features of CNC and VMC technology is precision. The ability to program exact dimensions means manufacturers can produce high-quality components consistently. This level of accuracy can reduce material waste by up to 20%, saving costs.

Increased Efficiency

CNC and VMC machines can operate continuously, which significantly boosts productivity. For example, during a 24-hour production run, these machines can manufacture thousands of components without the need for breaks. This efficiency is especially crucial for high-volume production settings.

Cost Effectiveness

While the initial investment in CNC and VMC machinery can be high, the long-term savings are meaningful. Reductions in labor costs and material waste lead to a quicker return on investment. Many companies find that they recoup their initial costs within three years, highlighting the financial benefits of these advanced systems.

Flexibility

CNC and VMC machines can easily adapt to varying production demands. Whether it's producing a prototype or large-scale orders, these machines can switch tasks with minimal downtime. This flexibility enables manufacturers to respond swiftly to market changes.

The Future of CNC and VMC Technologies

The future of CNC and VMC technology looks bright. With advancements in artificial intelligence and machine learning, these machines are becoming even smarter. For example, predictive maintenance algorithms are being implemented to prevent equipment failure before it occurs. Companies that adopt these innovations can expect to see a 15% reduction in downtime.

Moreover, advancements in materials science are likely to expand the applications of CNC and VMC technologies. Manufacturers will soon be able to work with advanced materials that were previously challenging to process, pushing the boundaries of design and functionality.

Embracing Tomorrow’s Manufacturing Today

CNC and VMC technologies have fundamentally changed the landscape of modern manufacturing. Their ability to increase efficiency, maintain precision, and adapt to various manufacturing needs positions them as essential tools across multiple industries.

For businesses eager to stay competitive, investing in CNC and VMC technology is not just a trend but a necessity. By embracing these innovations, manufacturers can enhance their production processes and meet the evolving demands of the market. As we explore the capabilities of these machines, it is clear that they will continue to shape the future of manufacturing.

Comments