Unleashing the Future: The Game-Changing Impact of CNC Technology in the Automobile Industry

- triotechcncsolutio

- Apr 8

- 3 min read

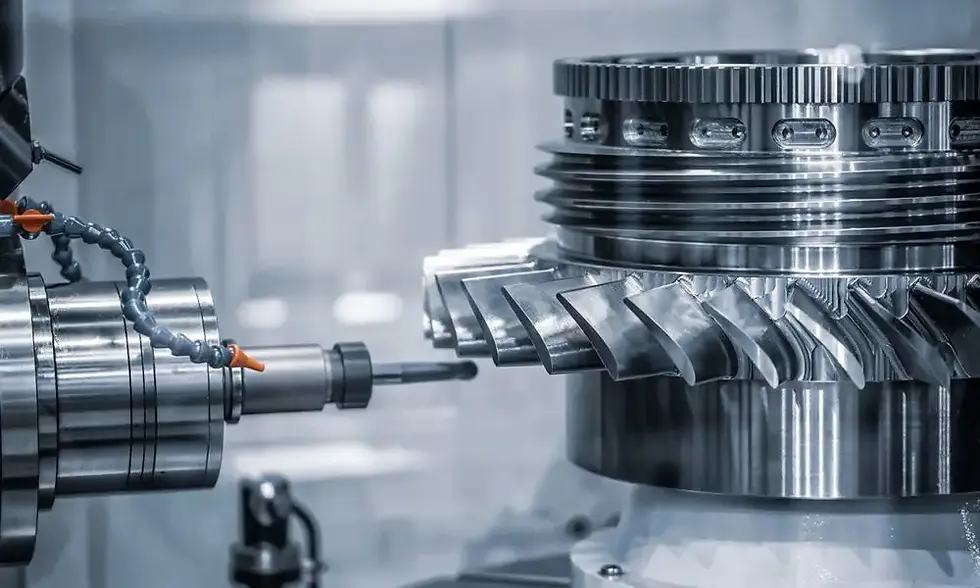

The automobile industry is experiencing a remarkable transformation, driven by advanced technologies that enhance both the manufacturing process and the products we drive. One such innovation is Computer Numerical Control (CNC) technology. This game-changer is paving the way for unparalleled precision, efficiency, and creativity in automotive design and production.

CNC technology holds the power to revolutionize the automobile industry, allowing manufacturers to create complex parts with high accuracy and minimal waste. In this blog, we will explore how CNC technology impacts everything from prototyping and production to sustainable practices and customization.

Precision Engineering: The Core of CNC Technology

At the core of CNC technology is precision engineering. CNC machines are programmed to perform intricate operations such as cutting, milling, drilling, and grinding with exceptional accuracy. For example, manufacturers can produce components to within 0.001 inches of tolerance, a standard that traditional manufacturing methods struggle to achieve.

This precision results in parts that fit together seamlessly, which reduces defects, leading to enhanced vehicle performance and safety. The ability to create lighter, fuel-efficient vehicles while complying with safety standards was largely out of reach in past manufacturing practices. With CNC technology, this has become a reality.

Streamlining Production Processes

CNC technology not only boosts precision but also streamlines production processes. Automated CNC machines can run continuously, significantly speeding up manufacturing. Companies leveraging CNC technology have seen production rates increase by an impressive 50%.

Timely adjustments to production are crucial, especially in a fast-paced market where consumer preferences shift rapidly. For instance, a leading automotive manufacturer decreased its lead time by 30% after implementing CNC processes, allowing it to respond swiftly to new trends and consumer demands.

The blend of CNC machines with automation tools, like robotics and IoT (Internet of Things), amplifies production efficiency, ushering in a future where processes are not only faster but smarter.

Enhancing Customization and Flexibility

CNC technology excels in facilitating customization, providing consumers with more choices than ever. Traditional methods often confine manufacturers to standard parts. Today, creating bespoke components has become both straightforward and cost-effective.

For instance, automakers can offer personalized features like unique dashboard designs or specialized engine components. This flexibility lets manufacturers cater to various customer preferences while enhancing user experience and brand loyalty.

According to a recent survey, 70% of consumers expressed a desire for personalized vehicle options. This trend towards customization signifies a significant cultural shift in the automobile industry, where consumer-centric approaches are becoming the new norm.

Driving Sustainability in Manufacturing

In an age increasingly focused on sustainability, CNC technology plays a vital role in eco-friendly manufacturing practices. These machines optimize material usage, significantly reducing waste during production. For example, CNC processes can cut excess material scrap down by up to 90% compared to traditional methods.

Moreover, the precision and durability of CNC-produced components lead to more reliable vehicles, translating to fewer replacements and less overall waste. Enhanced accuracy also directly contributes to improved fuel efficiency, addressing the pressing need for sustainable practices within the industry.

As regulations around environmental impact become stricter, automakers leveraging CNC technology position themselves as leaders in creating eco-friendly products, ultimately meeting the growing consumer demand for sustainable options.

The Future of CNC Technology in the Automobile Industry

The potential of CNC technology in the automobile industry is vast and evolving. Advancements in AI and machine learning are set to enhance CNC operations, making them even smarter. For instance, integrating predictive maintenance can identify potential issues before they affect production, reducing downtimes and boosting productivity.

Additionally, as 3D printing technology evolves, its combination with CNC machining may redefine parts production. This integration could allow manufacturers to create intricate designs that traditional methods cannot achieve. The synergy of these technologies presents exciting possibilities for the future of automotive design and engineering.

The Road Ahead

The impact of CNC technology on the automobile industry is transformative and far-reaching. With enhanced precision, streamlined production, increased customization options, and sustainable practices, CNC technology is not just an innovation; it is a catalyst for change.

As the industry embraces these advancements, we can expect vehicles that are not only more efficient and eco-friendly but also tailored to individual consumer preferences.

The future of the automobile industry shines brightly, driven by the revolutionary influence of CNC technology. As we move forward, one undeniable truth remains: the open road ahead will be shaped by innovation, precision, and a comprehensive understanding of what drivers truly seek.

Comments